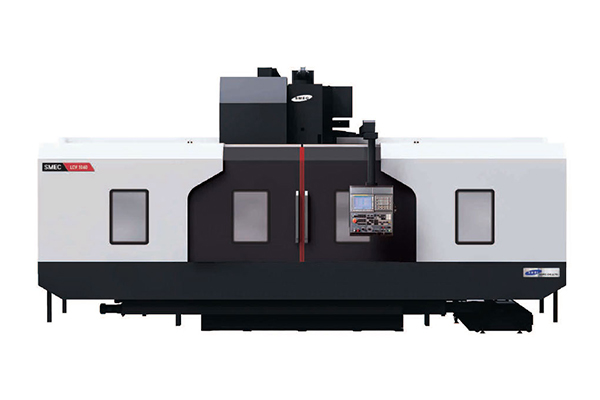

| Table |

Table size |

mm |

2800 × 1060 |

| Table surface |

|

22H8 x p150 x 7ea |

| Loading capacity |

kg |

5000 |

| ATC |

Magazine Capacity |

ea |

30[40] |

| Tool Shank |

|

BT50 |

| Tooling changing method |

|

Double Arm Swing |

| Tool Changing Time (T-T) |

sec |

2.5 |

| Tool Selection |

- |

Memory random |

| Max. Tool dia. (adjacent empty) |

mm |

100(195) |

| Max. Tool Length / Weight |

mm/kgf |

300/15 |

| Pull stud type |

|

MAS P50T-90° |

| Travel |

Distance from table surface to spindle nose |

mm |

200 ~ 1,100[400 ~ 1,300] |

| Spindle |

Spindle speed |

rpm |

7000 |

| Spindle motor (Cont./Max) |

kW |

15/18.5 |

| Torque (Cont. /Max.) |

N.m |

498.2/768 |

| Travels |

X-axis travel |

mm |

2500 |

| Y-axis travel |

mm |

1060 |

| Z-axis travel |

mm |

900 |

| Machine |

Size (with Side Chip conveyor) L×W×H |

mm |

- |

| Size (with Rear Chip conveyor) L×W×H |

mm |

6700 x 4841(5,338) x 3660 |

| Machine weight |

kg |

25000 |

| Coolant tank capacity |

Litre |

645 |

| Electric power supply |

|

kVA/V |

47/220 |

| Controller |

|

|

Fanuc |